Overview of the GlowForge 3D Laser Printer

The concept of a 3D laser printer has been around since the 1980s, when scientists in Japan first began experimenting with the idea. However, it wasn't until 2014 that the technology was truly put to use, when GlowForge released its groundbreaking 3D laser printer. This device revolutionized the manufacturing industry by allowing for rapid production and prototyping of parts and components. It also opened up many new possibilities for creative projects such as custom jewelry, art pieces, and unique gifts.

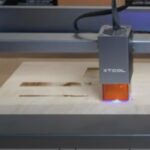

What makes GlowForge so special is the way it works; it uses lasers to precisely cut or etch materials like wood, metal, acrylic, and even fabric. This means that instead of using manual labor or traditional cutting tools such as saws or routers, you can now do intricate work quickly and accurately with just a press of a button. The laser can be programmed to cut shapes in predetermined sizes or patterns with incredible precision: every single detail will be perfect down to the last millimeter. In addition to cutting through materials, GlowForge can also mark them with etched details. This feature makes it especially useful for labeling items such as parts or packaging materials with barcodes or graphics.

Glowforge has quickly become an invaluable tool for manufacturers and entrepreneurs alike due to its versatility and affordability. Highly precise parts can be created quickly without any manual labor involved; this not only reduces labor costs but also allows for faster production times which translates into higher profits for businesses. With Glowforge’s advanced features such as multiple levels of engravement depth control, adjustable speed settings and more than 450 compatible materials available, users are able to make highly intricate designs more easily than ever before.

The possibilities don’t end there; the Glowforge system is also popular among those who dabble in arts & crafts projects. Whether you’re making your own birthday cards or creating custom jewelry pieces from scratch – anything is possible with this innovative technology! As the demand for personalized products continues to grow each year, Glowforge has become an invaluable tool for small business owners who wish to stand out amidst competitors offering mass-produced products.

No doubt about it – GlowForge is certainly a revolutionary 3D laser printer that has changed manufacturing processes forever! With its limitless potential applications in various industries such as medicine, automotive engineering, and aerospace engineering – we’re sure this technology will continue to surprise us time and again in terms of what it can do!

Features and Capabilities of the GlowForge

GlowForge is a revolutionary 3D laser printer designed to transform the way we create products and prototypes. This technology uses a combination of lasers, optics, and computer-controlled motion to precisely cut, engrave, or mark almost any material with incredible accuracy and speed. It has the potential to revolutionize manufacturing as it allows users to quickly and easily produce parts with fewer steps than traditional methods. The Glowforge can also be used for arts & crafts projects such as engraving wood, leather, acrylics, paper goods, plastics, metals, and more.

- Cut, Engrave, & Mark: The GlowForge is able to precisely cut, engrave, or mark almost any material.

- Speed and Accuracy: It has the capability of producing parts quickly with great accuracy.

- Various Materials Compatible: The GlowForge can work on materials such as wood, leather, acrylics, paper goods, plastics, and metals.

- Easy-to-Use Software Interface: Users are able to control the machine via an easy-to-use software interface.

- Automated Focusing System: Its automated focusing system helps users achieve accurate results in less time.

- Networking Capability: Incorporates networking capabilities so multiple machines can be used at once for large scale projects.

- Single Pass Printing Technology: Utilizes single pass printing technology that allows users to print complex 3D designs without sacrificing speed or quality.

Potential Applications for Manufacturing Industries

The potential applications for manufacturing industries are numerous and include:

- Automotive parts production: The GlowForge can be used to quickly and accurately produce precision parts for cars, trucks, and other vehicles. Since it operates with lasers, the resulting parts will have extremely tight tolerances that meet the industry's most demanding specifications.

- Medical device manufacturing: With its high level of accuracy and precision, the GlowForge is perfect for producing medical devices like implants and prosthetics. The laser can cut through a range of materials such as titanium, stainless steel, acrylics, and composites with extreme accuracy. This makes it ideal for creating complex shapes or intricate designs for medical applications.

- Aerospace components: The GlowForge is capable of fabricating small aerospace components such as aircraft wings or fuselages with great precision. It can also cut through materials like aluminum or titanium alloy which are commonly used in aerospace industry.

- Electronics manufacturing: The laser technology found in the GlowForge makes it perfect for creating circuit boards or other electrical components quickly and accurately. It can engrave intricate patterns on copper sheets to create circuit boards that meet exact specifications.

- Jewelry making: Jewelry makers and artisans can use the GlowForge to engrave detailed patterns or lettering on precious stones with incredible accuracy. This advanced technology allows users to quickly create beautiful jewelry pieces with unparalleled detail.

- Rapid prototyping: By allowing users to rapidly prototype products without costly tooling costs, the GlowForge significantly reduces time to market for new product ideas. This makes it an ideal choice when iterating on designs or building prototypes quickly to test out new ideas in the market before investing in large scale production runs.

Implications for the Future

The GlowForge 3D laser printer has the potential to revolutionize manufacturing processes and create new possibilities for production. With its ability to quickly and accurately produce parts, it could drastically reduce lead times in many industries while simultaneously increasing quality. Additionally, its networking capabilities make it possible to use multiple machines at once for large scale projects or rapid prototyping. This technology will open up a world of opportunities for designers, engineers, manufacturers and more by allowing them to quickly create complex designs with incredible accuracy. The implications of this revolutionary machine are far-reaching and have the potential to transform the way things are made in the years ahead.

- More efficient and cost-effective manufacturing processes

- Faster time to market for new products

- Greater accuracy in production of medical devices, aerospace components, electronics, and jewelry

- Increased customization capabilities with laser engraving or cutting technology

- Increased safety from automated focusing systems and networking capabilities

- Lower tooling costs due to rapid prototyping capabilities

- Possibility of large scale projects being handled by multiple machines simultaneously

How to Use a Glowforge in Arts & Crafts Projects

- Engraving – Use the GlowForge to engrave intricate patterns and lettering on a variety of materials, including wood, stone, metal, plastic and more.

- Cutting – The laser can be used to cut through different types of materials with great precision for precise shapes or designs.

- Etching – Create detailed etchings into glassware or other objects using the laser’s focused beam of light at low temperatures.

- Printing – Print 3D models from a file in minutes by using the machine’s included software for smooth surfaces that require no cleanup after printing is complete.

- Carving – Easily carve out beautiful designs from hardwood with incredible detail in minutes thanks to its automated focusing system and networking capabilities that allow multiple machines to work together on large projects simultaneously

- Stenciling - Making custom stencils has never been easier thanks to its powerful lasers which can precisely cut out small letters or symbols without any difficulty

- Heat Transfer - With high-precision control over heat settings you can age metals quicker than ever before while also creating embossed finishes on fabric items like t-shirts or bags

- Engraved Wood - The GlowForge is capable of creating beautiful engraved wood designs with perfect accuracy and detail. This can be used to create personalized gifts, signs, or decorations.

The possibilities with the GlowForge 3D laser printer are near endless and will open up new ways for makers and artisans to express their creativity in ways that weren’t possible before. With the potential to revolutionize manufacturing processes and create new possibilities for production, its implications for the future are far-reaching.

FAQ

Q: What materials can the GlowForge cut?

A: The Glowforge can work on a range of materials, including wood, stone, metal, plastic, and more.

Q: Can multiple machines be used for large projects?

A: Yes! The networking capabilities allow for multiple machines to be used simultaneously, which is perfect for larger scale projects or rapid prototyping.

Q: Is it safe to use?

A: Yes! It has an automated focusing system and safety measures in place to minimize any risks. Additionally, all its parts are UL-certified, so you know that it meets all safety regulations.

Conclusion

The GlowForge 3D laser printer is truly revolutionary technology that has the potential to revolutionize manufacturing processes and create new possibilities for production. Its precise cutting and engraving capabilities mean that projects can be finished quickly with incredible accuracy, making it ideal for a range of applications from arts & crafts to large scale manufacturing. With its safety regulations in place and the capability to use multiple machines at once, this machine has the potential to make a big impact in the future of manufacturing.

By exploring the features, capabilities, and potential applications of this innovative technology, we can see just how powerful it is and how it can be used to create amazing works of art or streamline traditional manufacturing processes. The future of the GlowForge 3D laser printer is sure to be exciting!

- Cricut Hat Press: A Comprehensive Guide on Usage - August 13, 2023

- Unlocking Creativity with the Cricut Joy: A Comprehensive Guide - August 12, 2023

- The Ultimate Guide to the Cricut Maker Bundle - August 11, 2023